Value-added Services

Heat-treating

After waterjet cutting and fabricating your annealed metal machine parts, knives, custom sign lettering, and more, we heat-treat your project to harden the soft metal, making it durable and easier to polish.

Polishing

If you want your finished project to have an aesthetically pleasing, finished look, you can depend on us to provide you with top-quality metal polishing services. From satin-finish knives to mirror-finish custom signage and more, we've achieved beautiful metal surface treatment results for companies like Bark River Knife & Tool, Coach, Tory Burch, and Ralph Lauren.

Plating

When your project requires metal plating to improve corrosion resistance or durability, increase magnetism, or enhance the decorative appeal, our experts can streamline your workflow by adding plating services to your milling and fabrication project. Plating is a process by which a thin layer of metal substrates, such as rhodium, tin, silver, gold, copper, nickel, chrome, cadmium, or zinc, is added as an outer coating to your fabricated component. The New Jersey Waterjet team will help you determine whether metal plating would add value to your project.

Welding

New Jersey Waterjet is dedicated to helping you achieve your project goals efficiently. If you need materials fused, we can provide post-waterjet welding services. We've provided welding services for automobile and airplane parts, construction materials, and pharmaceutical and food production machinery for companies that include Canfield Scientific, Aero Farms, and Meto Systems.

Assembly

If your waterjet cutting output requires assembly to create a finished product, depend on New Jersey Waterjet to help save you time and money. For example, we've waterjet cut knife blanks and then provided knife assembly services to attach handles, delivering fully assembled knives to our clients.

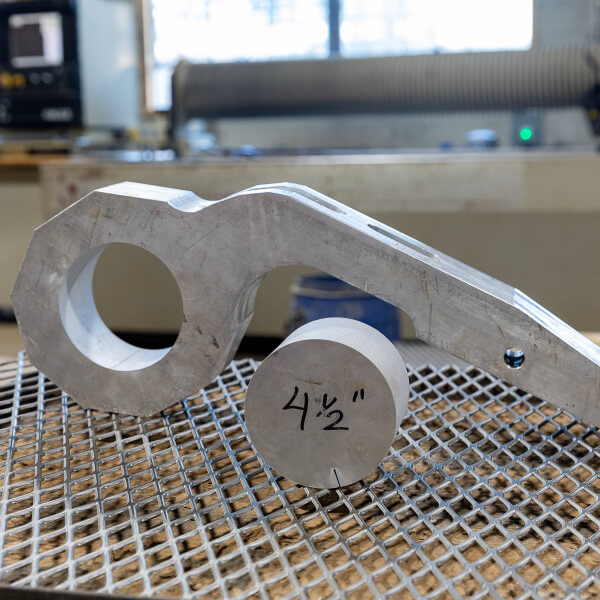

Reverse Engineering of Parts

Need machine replacement parts, but you don't have CAD designs? The New Jersey Waterjet experts can use the existing parts to reverse engineer CAD drawings for any object and use these drawings to produce customized, high-quality output.

CAD Design

We can help make your vision a reality by creating CAD drawings of your unique design from blueprints or a hand-drawn sketch, and then use our top-quality waterjet machines to produce the output you require.

Steel & Stainless Steel

Steel & Stainless Steel Aluminum

Aluminum Brass

Brass Composite Plastic

Composite Plastic Marble, Granite & Stone

Marble, Granite & Stone Titanium

Titanium